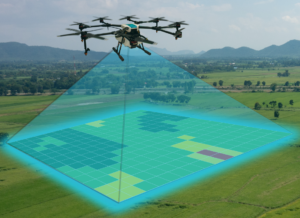

Drones

Drones, also referred to as unmanned aerial vehicles (UAVs) have many uses in the construction industry. As drone technology improves the variety of uses continues to increase. The goal of  utilizing drones on and off the construction site is to improve safety, efficiency, and cost-effectiveness. This is accomplished in many ways, including but not limited to –

utilizing drones on and off the construction site is to improve safety, efficiency, and cost-effectiveness. This is accomplished in many ways, including but not limited to –

- Improved safety and risk management: Drones have been used to monitor construction sites for a few years. Thye can be incredibly effective as they can capture and transmit real-time aerial images and videos. Additionally, drones can aid in the location of hazardous materials and working conditions that when identified early can prevent collapsing structures and machinery accidents.

- Progress monitoring: The real-time capture and transmission of aerial images and videos can also be used to monitor on-site progress.

- Marketing and promotions: The same method of capturing images and videos to monitor on-site progress can be used during construction or once construction has been completed to capture high resolution pictures and videos that can be used in marketing and promotion.

- Mapping and surveying: Drones can be utilized in the preconstruction phase during mapping and surveying. This is yet another use for the high-resolution aerial images that drones can capture. Mapping and surveying have traditionally been a labor-intensive and time-consuming processes requiring many different types of equipment to achieve precision and accuracy. Now, especially in recent years where in many places the heat has been more intense and less forgiving, drones can be utilized to save time and money, while potentially keeping workers from the harsh and damaging heat.

- Improved communication: Reliable and accurate communication is vital in any construction project. Drones can provide real-time imaging of the construction site contractors, sub-contractors, and clients alike.

- Environmental impact assessment: Similar to how drones can be used to perform mapping and surveying, drones can be used to contribute to environmental impact assessments.

Self-Healing Concrete

Researchers recently uncovered the secret behind the historic “self-healing” roman concrete. While this technology isn’t exactly new, it has seen a resurgence in recent years. The self-repairing factor of self-healing concrete is powered by bacterial precipitation which is why it is commonly referred to as “Bacterial Concrete” or “Bio Concrete”. Implementing self-healing concrete into construction can increase the longevity of a structure because it can self-repair some cracks and damage with no external treatment. Additionally, certain types of self-healing concrete have a higher compressive and flexural strength than traditional concrete. Self-healing concrete does come with disadvantages such as installation requires skilled labor, and the cost is nearly double that of traditional concrete.

Green Concrete

Similar to self-healing concrete, green concrete is not a new technology, however, innovations and improvements have been made in the field recently contributing to an increase in the accessibility and popularity of green concrete. Concrete is one of the world’s most consumed materials, and the concrete industry (manufacture, distribution, installation) is one of the world’s leading contributors to carbon emissions.

Green concrete can be a more environmentally friendly alternative to traditional concrete as it utilizes recycled concrete and the waste products from other industries. Using green concrete can reduce CO2 emissions from concrete manufacturing and reduce waste, as many types of green concrete supplement a portion of the cement in the concrete mixture with alternatives such as fly ash, silica fume, date palm ash, recycled glass, or blast furnace slag. This impacts carbon emissions immensely as the production of cement emits the most carbon out of all the steps of the concrete manufacturing process. The aggregate material is also often replaced or supplemented with recycled or greener materials. This may include waste plastic, recycled concrete and other demolition waste, or foundry sand.

Despite these advantages, green concrete has downsides. The manufacturing process of green concrete can be more complex, time-consuming, and costly. Green concrete also has higher water absorption and less flexural strength than traditional concrete.

Augment Reality

Augmented reality (AR) has found a place in the construction industry, and as technology and industry continue to evolve, the uses of augmented reality evolve with it. Augmented reality combines virtual reality with the real world, overlaying digital information into the viewer’s real-world environment. This means that using AR and VR technology, contractors, engineers, architects and many others in the construction field can present project models and ideas in three dimensions, and if necessary, to scale. Augmented reality has the potential to enhance jobsite safety, foster better collaboration and communication, and increase efficiency.

Augmented reality (AR) has found a place in the construction industry, and as technology and industry continue to evolve, the uses of augmented reality evolve with it. Augmented reality combines virtual reality with the real world, overlaying digital information into the viewer’s real-world environment. This means that using AR and VR technology, contractors, engineers, architects and many others in the construction field can present project models and ideas in three dimensions, and if necessary, to scale. Augmented reality has the potential to enhance jobsite safety, foster better collaboration and communication, and increase efficiency.

Augmented and virtual reality have also been utilized recently in training. Similar to applications like Microsoft Flight Simulator that can be used to simulate flight conditions, Augmented and virtual reality can be used to simulate construction site conditions and teach beginners how to operate machinery and handle potentially hazardous materials or situations. This has the potential to make training easier and more accessible, jobsites safer and more efficient, and alleviate some of the skilled labor shortages.

3D Printing Technology

3D printing technology is being utilized in the construction sector on both small-scale and large-scale. From homes to spare parts, 3D printing has been taking the construction industry by storm. If done correctly, 3D printing in construction can be faster, safer, and more environmentally friendly than traditional concrete construction. However, 3D printed structures are typically more expensive to rent or buy, construction of these structures requires more skilled labor, and because this technology is still in its infancy, there are still issues that may arise.

Combining the efficiency of 3D printing technology with the longevity of self-healing concrete, and the environmentally friendly aspects of green concrete could be revolutionary for the future of construction.

Conclusion

The construction industry affects everyone, from housing to employment to business, everyone is invested in construction. Like any other industry, construction is constantly evolving, and new innovative technologies come with it. With the introduction of new technology, every year construction has the potential to become faster, safer, and greener, paving the way for the industry as a whole to limit its negative effects on the environment and create more sustainable structures.