What is structural engineering?

Structural engineering is the branch of the discipline civil engineering responsible for designing the foundation and skeleton of a building. In an analogy comparing engineering to the human body, Dr. Zerbe likened a building’s structural engineering to the “bones that hold up the human body”. Hidden by the walls are the supports that bear the weight of the building. Another important factor considered by structural engineers is weather and disaster zones. The structure or “bones” of a building is what takes the brunt of natural disasters. Buildings must be able to withstand extreme conditions depending on the location.

What is the newest project at CIVE®?

The country’s first multi-story 3D printed house is coming to Houston, Texas. The brainchild of a partnership between CIVE®, HANNAH, and PERI 3D Construction, this project is a groundbreaking development in the 3D construction printing industry.

What were the goals going into this project?

According to Dr. Zerbe this is a “pilot project” meant to test the designs and machines to open the door for larger scale projects. “In the future we can have houses that are quickly built, sustainable, economical, good for the environment, and disaster resistant. n short, speed, economy, and sustainability,” Dr. Zerbe replied.

Have the goals been met?

“So far, the project has been successful, but it is still in progress,” Dr. Zerbe commented. Despite a few hiccups along the way, the first 3D printed, multi-story home is on its way to completion. Thanks to the hard work and dedication of all involved, we are on our way to making history.

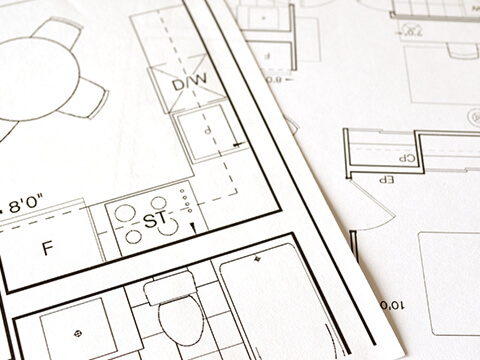

What challenges have been faced during this project?

To summarize Dr. Zerbe, like any structural engineering project, meticulous planning is required. When designing the structural elements of a building, “lives are at stake”. Responsible for the “strength and durability” of a building, structural engineering is the difference between a house and a pile of wood planks. Along with the problems involved with traditional construction, there are a multitude of additional challenges faced during 3D concrete printing. The printing process involves the printer (machine), the software, and the material or “ink”. This ink is a special concrete mixture which must be “mixed to the right ratio and consistency” as well as come out of the nozzle at a “specific speed and specific time”.

What materials are used in 3D concrete printing?

To paraphrase Dr. Zerbe, 3D concrete printing uses a reinforced concrete material. Reinforced concrete is concrete mixed or embedded with other materials to increase the tensile strength of the concrete. Unlike traditional buildings made of several materials, 3D printed buildings are made exclusively, or almost exclusively, of the printing material.

How does this project pave the way for the ever evolving construction landscape to be steered more towards 3D printing?

This project is meant to function as a data gathering and research project and according to Dr. Zerbe is “the stepping-stone” toward larger scale projects such as multi-family homes and 3-story buildings.