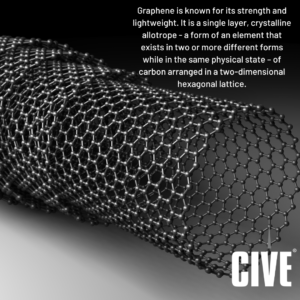

Graphene

Graphene is known for its strength and lightweight. It is a single layer, crystalline allotrope – a form of an element that exists in two or more different forms while in the same physical state – of carbon arranged in a two-dimensional hexagonal lattice. As the thinnest material known to man, graphene boasts extraordinary flexibility and elasticity as well as high thermal conductivity and  high electrical conductivity. With a reported strength 200 times stronger than steel, graphene has the potential to revolutionize the construction industry, but it cannot do this alone. As of present, graphene cannot be used as the primary building material. However, graphene can be, and is being used to reinforce concrete, significantly increasing the concrete’s durability and tensile strength. Referred to as graphene concrete, this material is made by adding graphene infused water to traditional concrete to create a composite material. The resulting material is significantly less permeable than traditional concrete with higher compressive strength, flexural strength, tensile strength, and durability. Although the applications of graphene concrete are limited for now, as more research is done and further testing completed, graphene and graphene concrete could change concrete construction as we know it.

high electrical conductivity. With a reported strength 200 times stronger than steel, graphene has the potential to revolutionize the construction industry, but it cannot do this alone. As of present, graphene cannot be used as the primary building material. However, graphene can be, and is being used to reinforce concrete, significantly increasing the concrete’s durability and tensile strength. Referred to as graphene concrete, this material is made by adding graphene infused water to traditional concrete to create a composite material. The resulting material is significantly less permeable than traditional concrete with higher compressive strength, flexural strength, tensile strength, and durability. Although the applications of graphene concrete are limited for now, as more research is done and further testing completed, graphene and graphene concrete could change concrete construction as we know it.

3D-Printed Concrete and other 3D-Printed Materials

Although 3D-printed concrete is not a new material, its popularity has skyrocketed in recent years leading to the refinement of materials, processes, and technology. Large scale 3D printing with concrete is easier and more accessible than ever before. With machines that can run overnight lessening build time and concrete that can cure and set in its final location instead of having to be moved and maneuvered, the possibilities and potential for 3D concrete construction are seemingly endless. If you’re interested in 3D-printed concrete, check out The History of Additive Construction.

3D printing technology is also being used in other construction applications such as creating lightweight, cement-free, insulated building elements. Made from mineral foam, these walls are incredibly versatile and were specifically designed to limit material use, costs, and labor requirements associated with the production and installation of building elements. While not a total replacement for concrete, this material can replace some concrete elements and can be used in conjunction with other concrete elements and other materials as a more sustainable alternative to strictly traditional concrete building. As the world population continues to grow, requiring more and more construction, foam 3D printing (F3DP) that has lower operational energy cost and consumes less materials could be the answer to many looming questions and concerns.

Mycelium Composites

Mycelium is the network of filaments (hyphae) that make up the root-like structure of fungus. These mycelium composites, like most other new age construction materials came to be out of necessity and a desire for greener, more sustainable building materials. As one of the world’s leading producers of carbon emissions cement production and by extension, the construction industry has been under enormous pressure. Mycelium composites are a strong, lightweight, biodegradable alternative construction material that uses a low energy, biological manufacturing process which not only emits less carbon than alternative material manufacturing but actually sequesters carbon.

Mycelium composite has been used to successfully create bricks, furniture, insulation and other materials that can be, and have been, used in construction. With developments in research and technology mycelium composites present a low material cost, low energy cost, biodegradable, low density construction material alternative. However, mycelium composites have low structural strength and are not suitable for all structures or environments.

Hempcrete

Additionally, hempcrete is yet another sustainable alternative for concrete that has risen in popularity following the increasing pressure placed on the construction industry to be more sustainable. Hempcrete is a bio composite material made from the hemp plant by mixing the inner core of the plant with a lime-based binder. This is why hempcrete is also called hemplime. The resulting lightweight and insulating material sports cement-like properties at as low as an eight of the weight of traditional concrete. Although it cannot be used as a structural element, hempcrete is most commonly used as insulation infill panels that have traditionally been made from concrete, brick, or lumber.

Straw

One of the oldest building materials is making a comeback, straw. Straw bale houses come in two forms: load bearing and non-load bearing. Load bearing straw bale houses rely on the straw bales for primary structural support whereas non-load bearing straw bale houses use other materials – such as steel, concrete, or lumber – and use the straw bales to help insulate and maintain the  structure’s shape. Straw is very environmentally friendly and inexpensive in addition to being biodegradable and highly renewable.

structure’s shape. Straw is very environmentally friendly and inexpensive in addition to being biodegradable and highly renewable.

These structures also have several drawbacks, including but not limited to the following: Straw bales houses are more susceptible to moisture related damage and problem. Straw bale houses may attract insects and rodents at a higher rate than alternatives, but this can be prevented if the right measures are taken. Compared to traditional and some alternative construction materials, straw bale houses may require more maintenance because once the material protecting the straw bales from the elements weakens or degrades it must be replaced quickly and efficiently to avoid long term damage and effects.

Conclusion

Construction materials (new and revitalized) have been following similar trends for years. Innovation is leading to lightweight, prefabricated, low cost, more sustainable, and high-performance materials that can be mass produced at low environmental cost. The end goal is to create a sustainable, affordable material that can be mass produced and therefore widely available. Another trend popular in recent years is improved concrete. This can be seen in projects like 3D printed concrete buildings, hempcrete, graphene concrete, and green concrete. Engineered for sustainability, strength, durability, environmental resistance, efficiency, and cost effectiveness, these new concrete variants have taken the construction industry by storm and show no sign of stopping.

Sources

Bedarf, P., Szabo, A., Zanini, M., Dillenburger, B.: “Robotic 3D Printing of Geopolymer Foam for Lightweight and Insulating Building Elements”. In: 3D Printing and Additive Manufacturing (2023), doi: external page10.1089/3dp.2023.0183call_made

Jones, M. P., Mautner, A., Luenco, S., Bismarck, A., & John, S. (2020). Engineered mycelium composite construction materials from fungal biorefineries: A critical review. Materials & Design, 187, 108397. https://doi.org/10.1016/j.matdes.2019.108397