Key Aspects of Circular Design

Optimizing Resource Use: Several practices incorporated in circular design contribute to the optimization of resources. This includes but is not limited to emphasizing longevity and durability in construction, limited the use of new materials, as well as using primarily renewable and recyclable materials. For example, a building constructed to adhere to the principles of circular design may feature repurposed steel and recycled concrete.

Limiting or Offsetting Carbon Emissions: Circular design encourages energy efficiency by prioritizing energy efficient designs. Passive design strategies and architecture takes advantage of the climate and climate cycle  of the construction location to minimizes the need to central heating and cooling by creating natural ventilation, putting thought and intention into building orientation, and placing windows and walls with forethought. Additionally, adding (repurposed and recycled) high performance material can reduce energy consumption from heating and cooling as well as lighting. Circular design requires not only the construction of the structure be built according to the optimization specifications but also the usage of the building to continue to adhere to these standards. This may include installing energy efficient technology and appliances, as well as energy efficient and waste reducing electrical, ventilation, and plumbing systems.

of the construction location to minimizes the need to central heating and cooling by creating natural ventilation, putting thought and intention into building orientation, and placing windows and walls with forethought. Additionally, adding (repurposed and recycled) high performance material can reduce energy consumption from heating and cooling as well as lighting. Circular design requires not only the construction of the structure be built according to the optimization specifications but also the usage of the building to continue to adhere to these standards. This may include installing energy efficient technology and appliances, as well as energy efficient and waste reducing electrical, ventilation, and plumbing systems.

Waste Minimization: Another key aspect of circular design is waste minimization. Incorporating practices that encourage the use of recycled and repurposed materials as well as prioritizing resource efficiency. By making designs and construction resources efficient, the waste produced by the construction process can be lessened especially when used in conjunction with new technology that can minimize material use without compromising strength, integrity, durability, or aesthetics. The prevalence of prefabrication can also be associated with circular design as prefabricating elements can result in less material waste compared to onsite fabrications. This is because excess materials produced in the prefabrication process can be reused or recycled whereas much of the excess materials that are produced during onsite fabrication become construction waste.

End-of-life Planning: For many structures, in the event that the building cannot be repurposed or repaired, the end-of-life plan is often demolition in which the remaining materials are disposed of as construction waste. When designing and building to the specification of the circular design model, an end-of-life plan is essential. By considering how materials can be recovered, recycled, or reused at the design stage, end-of-life stage waste can be reduced, and material usage can be optimized. Where traditional design relies on demolition, circular design relies of deconstruction.

How are Companies Implementing Circular Design

Circular design is most effective when used as a holistic approach but it can still be beneficial to incorporate parts of circular design into the construction process. Not many buildings are constructed entirely to the specification of circular design and for many companies it isn’t feasible (at the moment) to implement construction process changes at that level, however, small changes made over time can completely revolutionize the way construction is viewed and the impact it has on both the environment and the economy.

For example, using quality repurposed materials is a great first step toward transitioning to circular design. This reduces the need for new raw materials to enter the economic system and reduces waste and byproducts. In addition to being more sustainable, the practice of using quality repurposed or recycled materials can also be more cost effective depending on the material, or materials being repurposed. Although some architects take this to the extreme, making structures entirely out of recycled materials such as the Steel House in Ransom Canyon, Texas by architect Robert Bruno and the Zig-Zag House by architect David Coleman, full-scale recycled building like this are rare and can be difficult to construct. Simple material swaps such as using recycled steel, recycled concrete, or repurposed lumber, when possible, can be a much more accessible and realistic option for design and construction firms.

Perhaps at some point in the near future, using repurposed materials like this can be incorporated as part of the standard practice for value engineering.

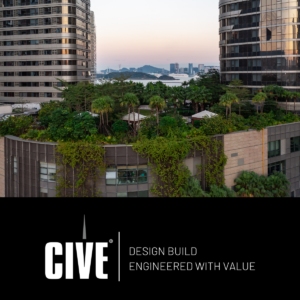

Many companies are also installing things such as rooftop gardens on new and existing buildings to offset carbon emissions. This practice is difficult to widely implement as many roofs are not structurally engineered to support the weight of rooftop gardens, however, designing and constructing rooftop  gardens for new construction is an efficient and environmentally friendly way to utilize unused, or underutilized space. Not only does this bring the structure closer to the goal of circular thereby contributing to the goal of a circular economy, space like rooftop garden that incorporate nature into the design can have positive health and productivity benefits for building inhabitants. To learn more about the benefits of incorporating nature into building design, check out our Biophilic Design blog.

gardens for new construction is an efficient and environmentally friendly way to utilize unused, or underutilized space. Not only does this bring the structure closer to the goal of circular thereby contributing to the goal of a circular economy, space like rooftop garden that incorporate nature into the design can have positive health and productivity benefits for building inhabitants. To learn more about the benefits of incorporating nature into building design, check out our Biophilic Design blog.

The gradual movement toward modular and flexible design also represents a method by which construction and architectural firms can and are incorporating circular design. Structures designed with modularity and flexibility in mind allow for easier adaptation, repair, and upgrading. This means that instead of demolishing a building and carting the remains off to a landfill, producing more construction waste and pollution, these structures can be adapted for new uses, repaired, or deconstructed so parts can be reused and repurposed. Adaptability extends the life cycle of buildings and structures contributing to their longevity which in turn reduces waste and the need for new, potentially harmful construction.

Learn more about Modular Design.

Conclusion

Circular design is how the construction industry fits into the circular economy model. With primary goals like sustainability and waste reduction, it has the potential to completely revolutionize the construction process. By prioritizing deconstruction instead of demolition, along with recycling and repurposing, and end-of-life planning, circular design emphasizes the use of forethought and attempts to create a construction process that is better for the present and the future.

With Gen Z up and coming in full force, their design and construction needs vary greatly from the previous generations. Beginning circular design trends now will create a healthier and more practical industry for them later. Since they tend to gravitate to less is more, they want buildings and spaces that do the same.