How is Bendable Concrete Made?

Bendable concrete is made by altering the composition of traditional concrete. This is done by incorporating fiber such as polyvinyl alcohol (PVA) or polyethylene (PE), into a cementitious mix. This requires several carefully excused processes including:

Material Selection – This is the point in the manufacturing process where the fibers responsible for the increased tensile strength and ductility of bendable concrete are selected and added to the mixture of traditional concrete materials. Concrete is typically made from cement, sand, water, and chemical admixtures with the cement and sand serving as the primary binders. Bendable concrete simply takes these materials and incorporates fibers as mentioned above.

Mix Design Optimization – This step ensures that the correct ratio of materials is incorporated into the cementitious composite to achieve the desired design and design properties.

Molding and Finishing – Once the materials are selected and the proper concrete mix is achieved, theECC mixture is poured into the desired forms or molds. Once poured, the surface is smoothed over or finished.

Curing – Like other concrete, ECC must have time to cure in order to perform at its desired strength and ductility. This means monitoring and maintaining moisture content and temperature. The curing process for bendable concrete can take between 7 to 28 days. It can be extremely variable.

What are the Advantages of Bendable Concrete?

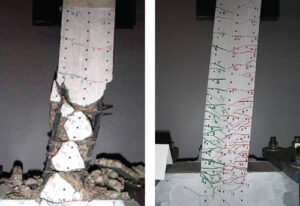

- Improved Ductility – Compared to traditional concrete, bendable concrete can withstand more ductile strain or deformations without breaking and while maintaining its strength. This makes bendable concrete more resistant to the extreme winds of natural disaster and the forces of earthquakes.

- Self-healing – Similar to the self-healing properties of the infamous Roman concrete, bendable concrete is able to repair micro-cracks, reducing maintenance requirements and extending the service life of structures.

- Reduce permeability – Bendable concrete’s tight crack width reduces chloride ion and water penetration of the material which increases durability and corrosion resistance.

Disadvantages of Bendable Concrete?

- Limited Availability – Bendable concrete is a relatively new technology for mass construction and therefore is not as widely available as traditional concrete.

- Increased Difficulty – ECC is harder to work with than traditional concrete. Proper mixing and application of bendable concrete require expertise that may not be readily available in all regions.

- Cost – Because bendable concrete requires additional material in the form of fiber additives to achieve its proper function that traditional concrete does not, bendable concrete can be more expensive than traditional concrete.

What are the Environmental Impacts of Bendable Concrete?

ECC production has both positive and negative environmental impacts. The production of cement contributes significantly to global CO2 emissions. Additionally, the environmental impacts of the synthetic fibers, such as PVA or PE, that are used in bendable concrete are still being explored. However, due to the potential for lower material consumption, bendable concrete may contribute to reduced CO2 emissions compared to traditional concrete.

Is Bendable Concrete Natural Disaster Resistant?

Bendable concrete has high ductility and flexibility making it well-suited to withstand natural disasters. Its unique properties make it an ideal choice for use in seismically active regions or areas prone to hurricanes, floods, and other natural hazards. Properties such as improved performance under dynamic loads, reduced required maintenance and its self-healing properties make it a promising new material for disaster zones. However, disaster resistant is not the same as disaster proof, and proper testing must be conducted for further data collection.

Conclusion

Bendable concrete is a promising new material for use in the construction industry. With further testing and refinement it can be more eco-friendly, cost effective, and disaster resistant than traditional concrete. There are even recent advancements in ECC technology allowing for cement-free bendable concrete, further reducing the carbon footprint. With the potential to be in a variety of structures from bridges to high-rises ECC could change construction for the better.