What is Cross-Laminated Timber?

Also referred to as X-Lam, cross-laminated timber (CLT) is an engineered wood panel system consisting of layered wood boards (usually in groupings of 3, 5, 7, or 11) stacked crosswise and adhered together. First popularized in Europe and Asia before being imported into North America, this method of stacking the pieces crosswise, alternating the grains, both gives this type of engineered wood its name, and improves the panel’s dimensional stability.

Engineered timber refers to various construction materials including cross-laminated timber, laminated veneer lumber, laminated strand lumber, plywood, and particleboard. This engineered timber, also known as composite wood, consists of layers of wood products bound together with additives such as adhesives or hardware such as dowels.

Engineered timber comes with many advantages. It is strong and can be used as a supplement or replacement for concrete or steel in certain aspects of construction. It also maintains its shape and dimension better than traditional lumber with less shrinking and warping over time. Additionally, engineered wood is typically cheaper than solid wood. It is also more environmentally friendly as manufactured wood can, and often is, made from the scraps of other lumber products.

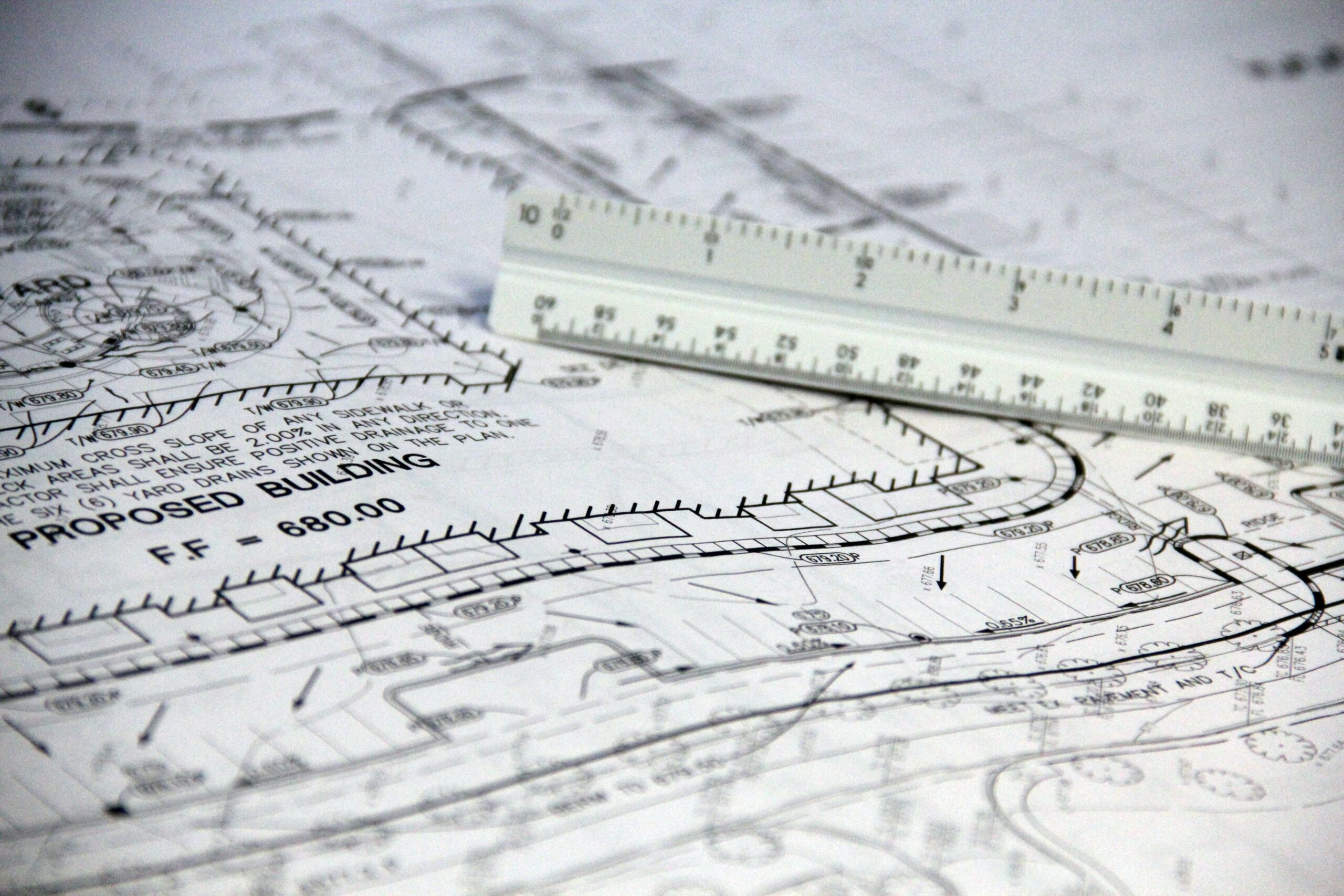

What is Cross-Laminated Timber used for in Construction and Engineering?

What is Cross-Laminated Timber used for in Construction and Engineering?

CLT can be used in most elements of a building’s structural engineering such as in walls, floors, roofs, beams, and decks depending on the thickness and number of layers. It can be used in elements as necessary as load-bearing beams and columns and for aesthetic purposes such as in furniture and flooring.

What are the Advantages of CLT?

Cross-laminated timber has many advantages. For example, CLT has a high load capacity. This is especially important when replacing traditional steel and lumber beams and columns with cross-laminated lumber. CLT also serves as a good insulator, both thermal and sound. Due to the structure of cross-laminated lumber wall panels, they are more fire resistant compared to traditional lumber. When quantifying a construction material’s fire resistance, fire resistance refers to the extent to which a material confines a fire and maintains its structural integrity and function during a fire. Compared to traditional lumber, steel, and concrete, cross-laminated timber has a shorter installation time.

Like many other materials becoming popular in recent years, cross-laminated timber is more environmentally friendly than traditional lumber and the production of CLT results in less waste compared to traditional timber. This production process also results in less air and water pollution and requires less energy than steel and concrete manufacturing. Wood, concrete, and steel are considered the primary building materials in construction with wood currently being the only naturally renewable resource among them. As mentioned in pervious paragraphs, cross-laminated timber can replace steel and concrete in certain aspects of construction due to its incredible stability and strength.

Disadvantages of Cross-Laminated Timber

Disadvantages of Cross-Laminated Timber

Along with the plethora of advantages comes various disadvantages. Because the demand for CLT is increasing, the demand for lumber is increasing and, in some countries, this is leading to an increase in deforestation. However, countries like the United States and other nations have strict laws and regulations in place to prevent such actions within their boarders. Additionally, because engineered lumber rapidly expanding technology in rapidly progressing field, cross-laminated timber is still relatively new. This results in limited data making CLT difficult for some design firms to implement.

How is Cross-Laminated Timber made?

The manufacturing of cross-laminated timber can typically be broken down into five simple steps.

- The selection of high-quality timber (many companies also require that the lumber be sustainably sourced).

- The lumber is grouped and planed. Grouping and planing is a process that turns cut and seasoned boards into lumber.

- Adhesives are applied and the panels are cross pressed together. Examples of adhesives used in the production of cross-laminated timber according to the Canadian Wood Council (CWC) include emulsion polymer isocyanate (EPI), one-component polyurethane (PUR), and phenolic types such as phenol-resorcinol formaldehyde (PRF).

- Then the CLT is cut and processed

- Finally, the finished cross-laminated timber is distributed.

Conclusion

CLT is an engineered timber that is taking the construction industry by storm. More sustainable than concrete and steel, more stable than traditional lumber, cross-laminated timber is a force to be reckoned with and something to consider during your next construction undertaking.